Stock Control

Vendure includes features to help manage your stock levels, stock allocations and back orders. The basic purpose is to help you keep track of how many of a given ProductVariant you have available to sell.

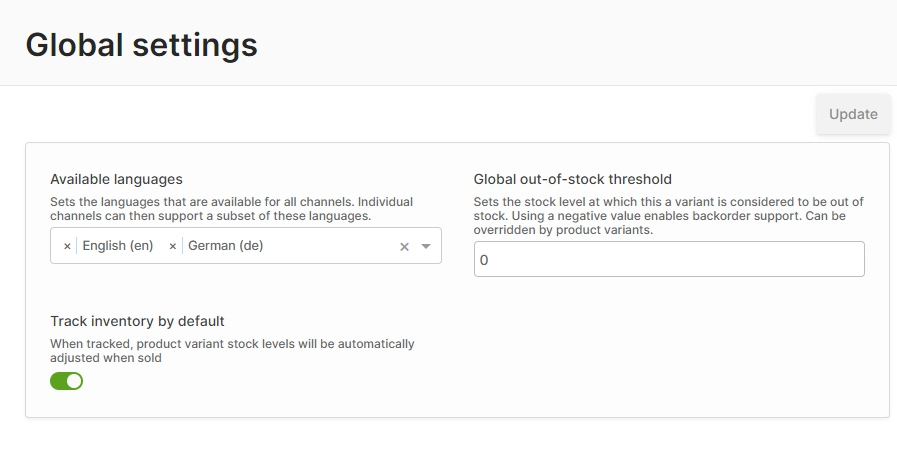

Stock control is enabled globally via the Global Settings:

It can be disabled if, for example, you manage your stock with a separate inventory management system and synchronize stock levels into Vendure automatically. The setting can also be overridden at the individual ProductVariant level.

Stock Locations

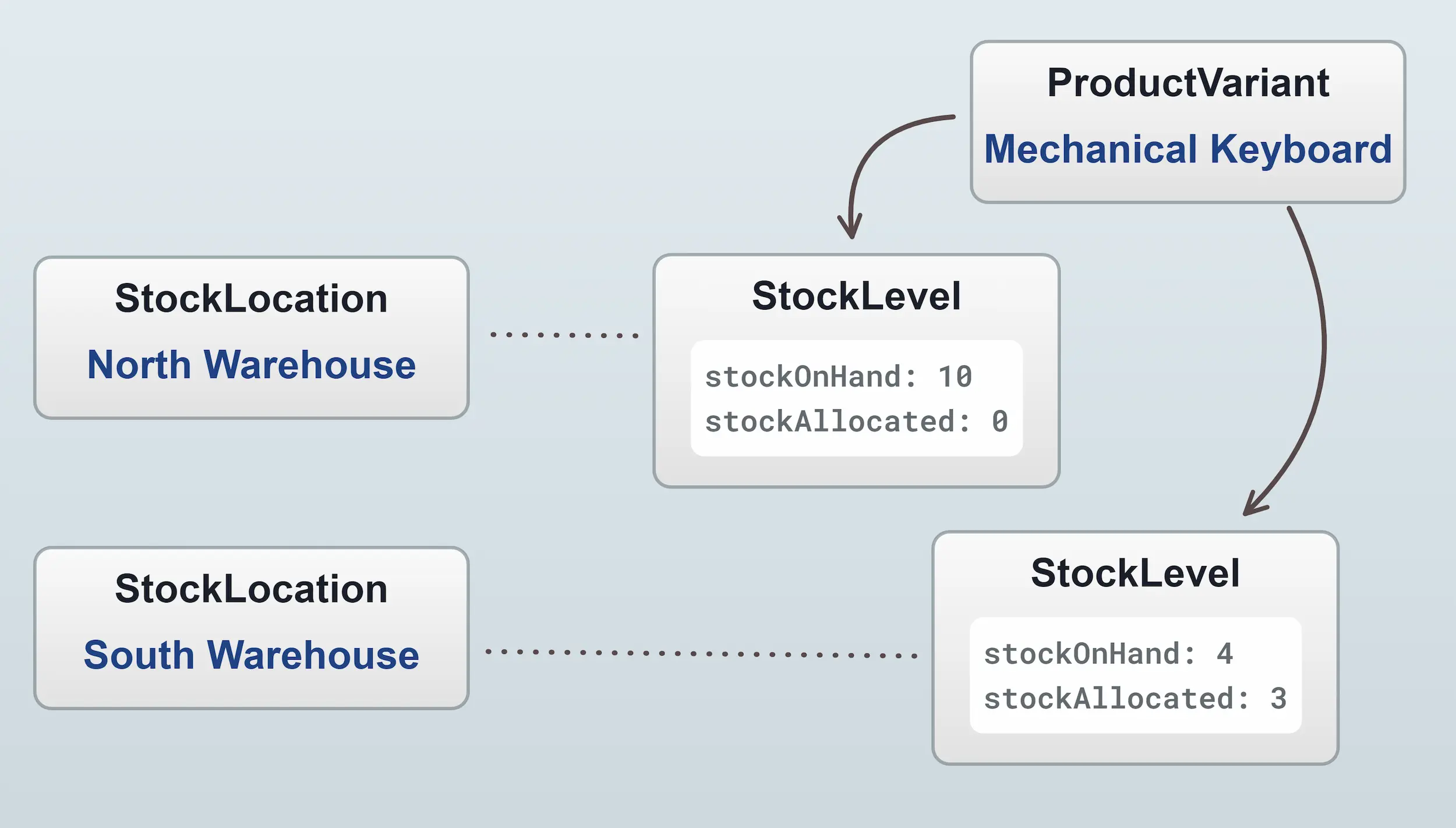

Vendure uses the concept of StockLocations to represent the physical locations where stock is stored. This could be a warehouse, a retail store, or any other location. If you do not have multiple stock locations, then you can simply use the default location which is created automatically.

Selecting a stock location

When you have multiple stock locations set up, you need a way to determine which location to use when querying stock levels and when allocating stock to orders. This is handled by the StockLocationStrategy. This strategy exposes a number of methods which are used to determine which location (or locations) to use when:

- querying stock levels (

getAvailableStock) - allocating stock to orders (

forAllocation) - releasing stock from orders (

forRelease) - creating sales upon fulfillment (

forSale) - returning items to stock upon cancellation (

forCancellation)

The default strategy is the DefaultStockLocationStrategy, which simply uses the default location for all of the above methods. This is suitable for all cases where there is just a single stock location.

If you have multiple stock locations, you'll need to implement a custom strategy which uses custom logic to determine which stock location to use. For instance, you could:

- Use the location with the most stock available

- Use the location closest to the customer

- Use the location which has the cheapest shipping cost

Displaying stock levels in the storefront

The StockDisplayStrategy is used to determine how stock levels are displayed in the storefront. The default strategy is the DefaultStockDisplayStrategy, which will only display one of three states: 'IN_STOCK', 'OUT_OF_STOCK' or 'LOW_STOCK'. This is to avoid exposing your exact stock levels to the public, which can sometimes be undesirable.

You can implement a custom strategy to display stock levels in a different way. Here's how you would implement a custom strategy to display exact stock levels:

import { RequestContext, StockDisplayStrategy, ProductVariant } from '@vendure/core';

export class ExactStockDisplayStrategy implements StockDisplayStrategy {

getStockLevel(ctx: RequestContext, productVariant: ProductVariant, saleableStockLevel: number): string {

return saleableStockLevel.toString();

}

}

This strategy is then used in your config:

import { VendureConfig } from '@vendure/core';

import { ExactStockDisplayStrategy } from './exact-stock-display-strategy';

export const config: VendureConfig = {

// ...

catalogOptions: {

stockDisplayStrategy: new ExactStockDisplayStrategy(),

},

};

Stock Control Concepts

- Stock on hand: This refers to the number of physical units of a particular variant which you have in stock right now. This can be zero or more, but not negative.

- Allocated: This refers to the number of units which have been assigned to Orders, but which have not yet been fulfilled.

- Out-of-stock threshold: This value determines the stock level at which the variant is considered "out of stock". This value is set globally, but can be overridden for specific variants. It defaults to

0. - Saleable: This means the number of units that can be sold right now. The formula is:

saleable = stockOnHand - allocated - outOfStockThreshold

Here's a table to better illustrate the relationship between these concepts:

| Stock on hand | Allocated | Out-of-stock threshold | Saleable |

|---|---|---|---|

| 10 | 0 | 0 | 10 |

| 10 | 0 | 3 | 7 |

| 10 | 5 | 0 | 5 |

| 10 | 5 | 3 | 2 |

| 10 | 10 | 0 | 0 |

| 10 | 10 | -5 | 5 |

The saleable value is what determines whether the customer is able to add a variant to an order. If there is 0 saleable stock, then any attempt to add to the order will result in an InsufficientStockError.

- Request

- Response

query AddItemToOrder {

addItemToOrder(productVariantId: 123, quantity: 150) {

...on Order {

id

code

totalQuantity

}

...on ErrorResult {

errorCode

message

}

...on InsufficientStockError {

errorCode

message

quantityAvailable

order {

id

totalQuantity

}

}

}

}

{

"data": {

"addItemToOrder": {

"errorCode": "INSUFFICIENT_STOCK_ERROR",

"message": "Only 105 items were added to the order due to insufficient stock",

"quantityAvailable": 105,

"order": {

"id": "2",

"totalQuantity": 106

}

}

}

}

Stock allocation

Allocation mean we are setting stock aside because it has been purchased but not yet shipped. It prevents us from selling more of a particular item than we are able to deliver.

By default, stock gets allocated to an order once the order transitions to the PaymentAuthorized or PaymentSettled state. This is defined by the DefaultStockAllocationStrategy. Using a custom StockAllocationStrategy you can define your own rules for when stock is allocated.

With the defaultFulfillmentProcess, allocated stock will be converted to sales and minused from the stockOnHand value when a Fulfillment is created.

Back orders

You may have noticed that the outOfStockThreshold value can be set to a negative number. This allows you to sell variants even when you don't physically have them in stock. This is known as a "back order".

Back orders can be really useful to allow orders to keep flowing even when stockOnHand temporarily drops to zero. For many businesses with predictable re-supply schedules they make a lot of sense.

Once a customer completes checkout, those variants in the order are marked as allocated. When a Fulfillment is created, those allocations are converted to Sales and the stockOnHand of each variant is adjusted. Fulfillments may only be created if there is sufficient stock on hand.

Stock movements

There is a StockMovement entity which records the history of stock changes. StockMovement is actually an abstract class, with the following concrete implementations:

Allocation: When stock is allocated to an order, before the order is fulfilled. Adds stock toallocated, which reduces the saleable stock.Sale: When allocated stock gets fulfilled. Removes stock fromallocatedas well asstockOnHand.Cancellation: When items from a fulfilled order are cancelled, the stock is returned tostockOnHand. Adds stock tostockOnHand.Release: When items which have been allocated (but not yet converted to sales via the creation of a Fulfillment) are cancelled. Removes stock fromallocated.StockAdjustment: A general-purpose stock adjustment. Adds or removes stock fromstockOnHand. Used when manually setting stock levels via the Admin UI, for example.

Stock movements can be queried via the ProductVariant.stockMovements. Here's an example where we query the stock levels and stock movements of a particular variant:

- Request

- Response

query GetStockMovements {

productVariant(id: 1) {

id

name

stockLevels {

stockLocation {

name

}

stockOnHand

stockAllocated

}

stockMovements {

items {

...on StockMovement {

createdAt

type

quantity

}

}

}

}

}

{

"data": {

"productVariant": {

"id": "1",

"name": "Laptop 13 inch 8GB",

"stockLevels": [

{

"stockLocation": {

"name": "Default Stock Location"

},

"stockOnHand": 100,

"stockAllocated": 0

}

],

"stockMovements": {

"items": [

{

"createdAt": "2023-07-13T13:21:10.000Z",

"type": "ADJUSTMENT",

"quantity": 100

}

]

}

}

}

}